Designing Ventilation Solutions with Biocomposites

Climecon is a forerunner in the ventilation industry, creating responsible, human-centric solutions that take into account the well-being of people, buildings, and the environment. It specialises in high-quality and sustainable ventilation solutions for buildings of all types. To achieve a lesser environmental impact, Climecon produces its ventilation nozzles by using Syklo’s biocomposite, Syklocomp.

Climecon is a Finnish company manufacturing ventilation products that combine functionality, Nordic design, and sustainability. With a mission to create better indoor air in a human-centric way, Climecon also sees sustainability as a core part of its business strategy.

In 2021, Climecon published its first Environmental Product Declaration (EPD), a verified carbon footprint calculation for its products. The results revealed that while production processes were relatively efficient, the materials used posed a significant environmental impact.

Conventional plastics were especially problematic, and reducing their footprint became a priority.

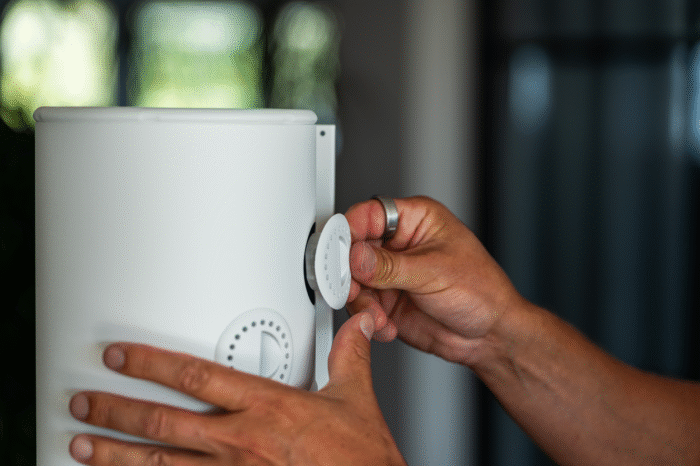

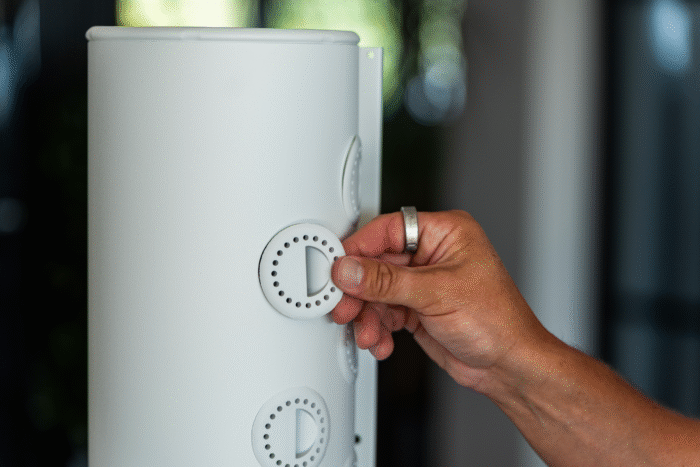

“Together with Syklo, we changed the material of our ventilation nozzle from traditional plastic to Syklo’s own biocomposite, Syklocomp”, describes Emma Piha, Sustainability Specialist at Climecon.

Biocomposite for an 80% Smaller Carbon Footprint

To address the challenge of producing plastic products in a more sustainable way, Climecon partnered with Syklo, a Finnish pioneer in bio-based and circular materials.

Together, they explored alternatives to traditional plastics, leading to the adoption of biocomposite materials in Climecon’s ventilation nozzles.

“We realised after our first EPD that there was a lot to be done regarding materials. Switching to Syklo’s biocomposite Syklocomp allowed us to meet our sustainability goals without compromising quality”, Piha explains.

Syklo has very specific and niche expertise in creating products that use less material, less energy and are durable, which is why Piha likes to work with them.

“The emissions of using biocomposite instead of conventional plastic are smaller by an average of 80%. The products even look better when they are made out of biocomposite“, she describes.

Leading the Way with Syklo’s Biocomposites

By adopting Syklo’s biocomposites, Climecon has significantly lowered the carbon footprint of its products and strengthened its role as a pioneer in sustainable ventilation solutions.

“We believe it’s our responsibility to create products that use less material, less energy, and are durable. By doing so, we help our clients achieve their environmental goals as well”, Piha says.

Benefits of Choosing Biocomposite Over Traditional Plastic

- 80% reduction in emissions from nozzle production

- Enhanced design and aesthetics without compromising performance

- Support for clients’ environmental targets through products with a much smaller footprint

Building the Future Together

Climecon sees this project as just the beginning. The success of the collaboration has laid the foundation for future projects with Syklo and opened doors to even more innovative material solutions.

“We recommend Syklo to any company looking to reduce their emissions or replace conventional plastics with sustainable alternatives. For us, choosing them has proven to be the right decision”, Piha concludes.